Back in 2012, the Occupational Safety & Health Administration (OSHA) updated the hazard communication regulation, 29 Code of Federal Regulation (CFR) §1910.1200 (HAZCOM). The purpose was to align the standard with the United Nations (UN) Globally Harmonized System (GHS) of Classification and Labelling of Chemicals. The updated HAZCOM regulation outlined a format for Safety Data Sheets (SDS) and what information was required to be included in an SDS. The standard allowed chemical manufacturers, importers, distributors, and employers until June 1, of 2015 to be in compliance with the standard.

Six years have passed since the compliance date and we still consistently receive and review SDSs that are not in compliance with the standard. In many cases, the hazard identification section does not include the required GHS information. Instead of the required pictograms, we may see a National Fire Prevention Association (NFPA) diamond or a Department of Transportation (DOT) placard, many times with signal words and hazard statements missing. In some cases, the exposure limits are incorrect or outdated and physical and chemical properties are missing. So, this begs the question, what are SDS good for? Even though these SDSs are incorrect, they still provide valuable information; however, missing information can have fatal consequences. SDSs should be carefully reviewed, and the manufacturer should be contacted if information is missing or does not seem accurate. Perhaps the manufacturer revised and issued a new SDS, and it simply needs to be implemented.

In general, the usefulness of an SDS is correlated to the effort that goes into its preparation and the completeness and accuracy of the information provided. That is why it is important to review your SDSs with a critical eye. Our safety team recently reviewed a series of SDSs for a client that had different compositional information listed in different section (Sections 3, 6, and 8 in particular). Sometimes it was a percent composition difference, but in some cases the chemical components listed in each section were different. If there are blatant errors in SDSs, how can we confidently discern if all the information is correct? And what if the emergency response procedures or the required personal protective equipment (PPE) sections are incorrect? An accurate and complete SDS can provide a wealth of information and in the case of a catastrophic event can mean the difference between life or death.

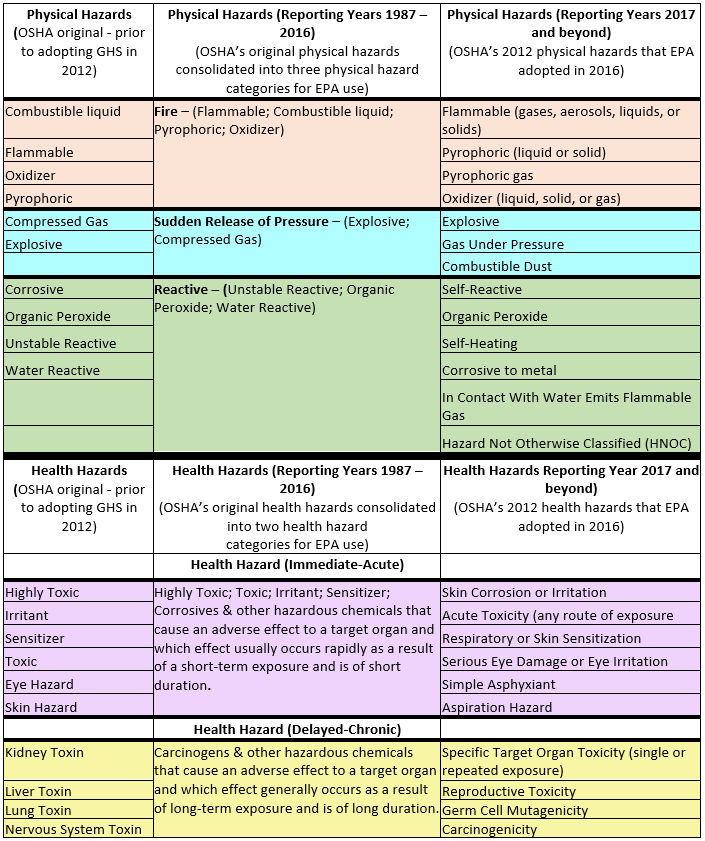

Accurate SDS information is also needed when filing Emergency Planning and Community Right-to-Know Act (EPCRA) Tier II Reporting or preparing Toxics Release Inventory (TRI) determination calculations and documentation. If an SDS has not been updated to the new GHS system, the EPA has provided the following crosswalk to convert old information into the Tier II reporting system hazard identification section:

Manufacturers are required to provide updated SDSs to their customers when an updated SDS is needed. If you are a manufacturer, you should be reviewing your products and their SDSs on a routine basis so you can properly identify changes and disseminate the revised SDSs as needed. Braun Intertec can review SDSs that have been provided to you or help you create and/or updates SDSs for your products. If you have any questions or need some assistance, please feel free to contact us.